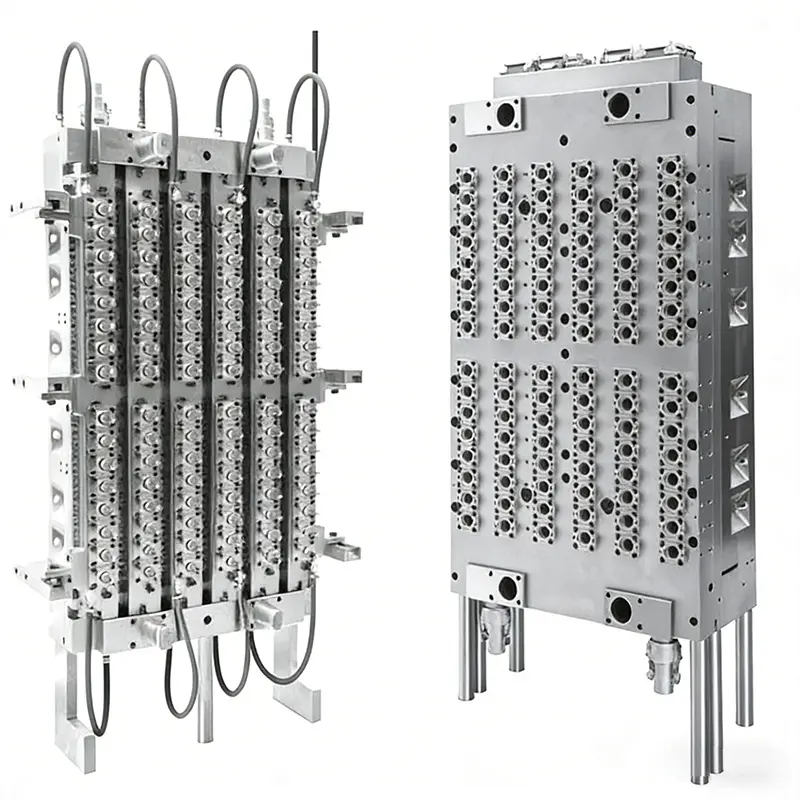

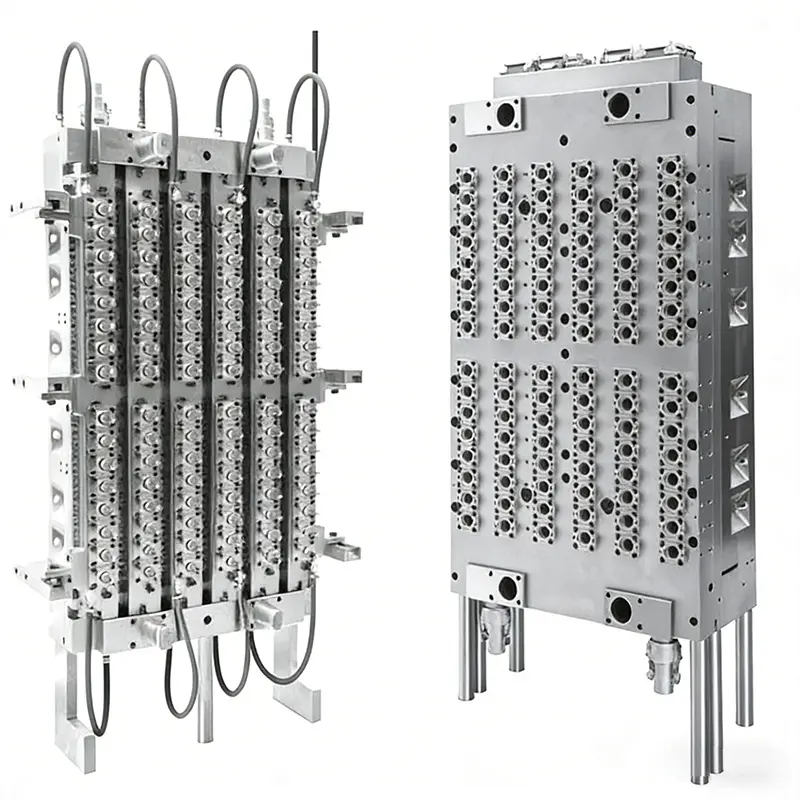

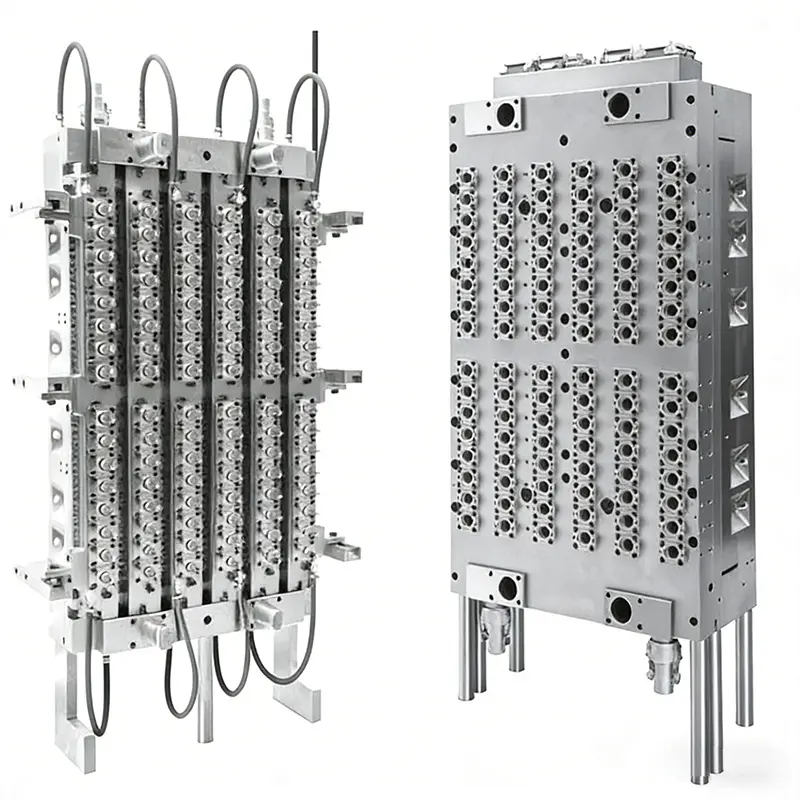

1、Preform Injection Mold

◆ The design of the die lip is composed of two parts.It can guarantee the same axis during the formation of perform.

◆ The reasonable design of cooling water channel can improve the cooling effect of the perform and guarantee a fast producing cycle.

◆ The formation components of the mold are using imported die steel 2316.It is rust-resistant and have undergone the hot treatment.

◆ The core plate,cavity plate and other structural parts are using 420 stainless steel,to ensure its corrosion resistance.

◆It is easy to maintain the mold.

◆Standard interchangeable die fittings.

◆Advanced mold design.Single mold can produce more than one type of perform.

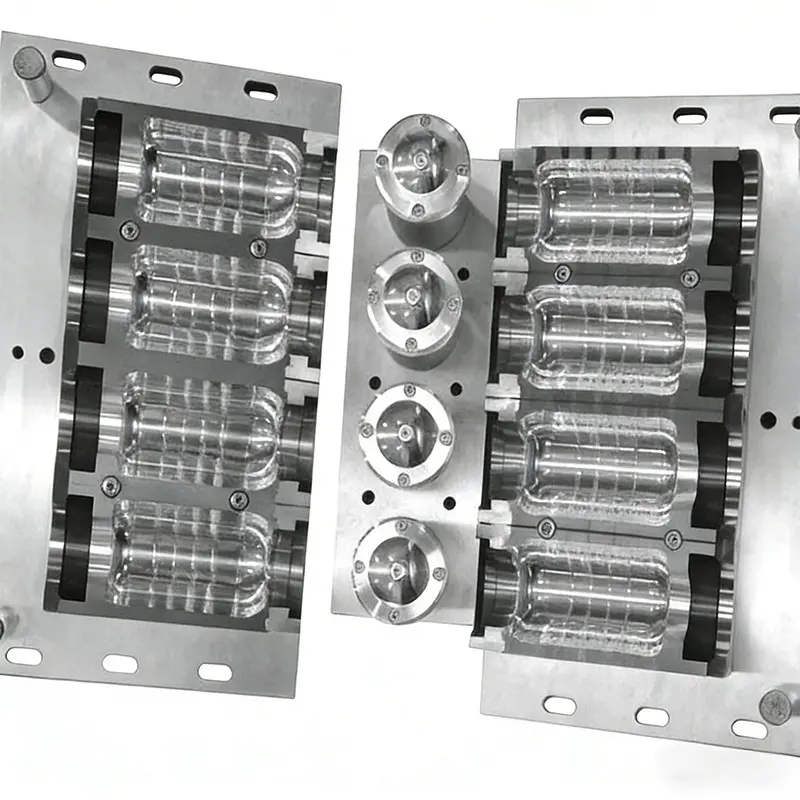

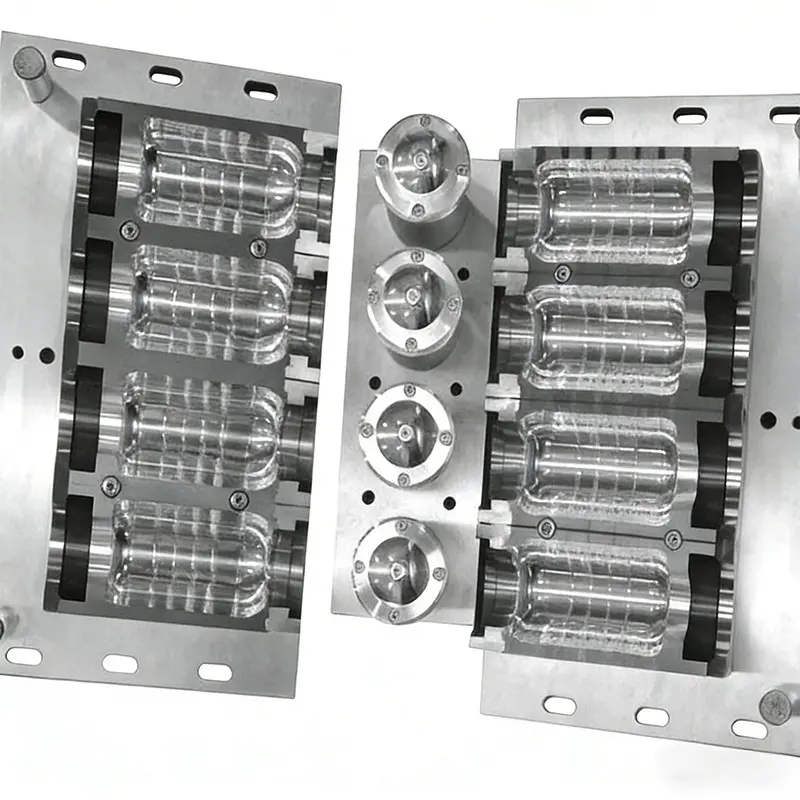

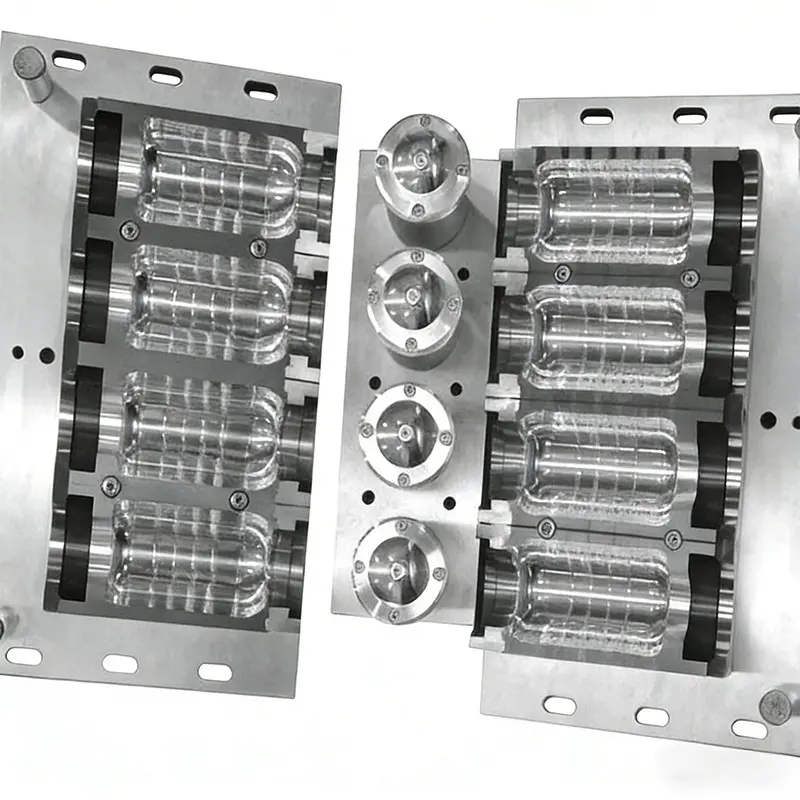

2、Blowing Mold

◆ The raw material is using high quality steel.

◆The plastic bottle is designed by advanced 3D software.

◆We can offer versatile bottle designs for selection.

◆ Reasonable design of the water cooling channel.

◆All the metal parts are processed by CNC machine.