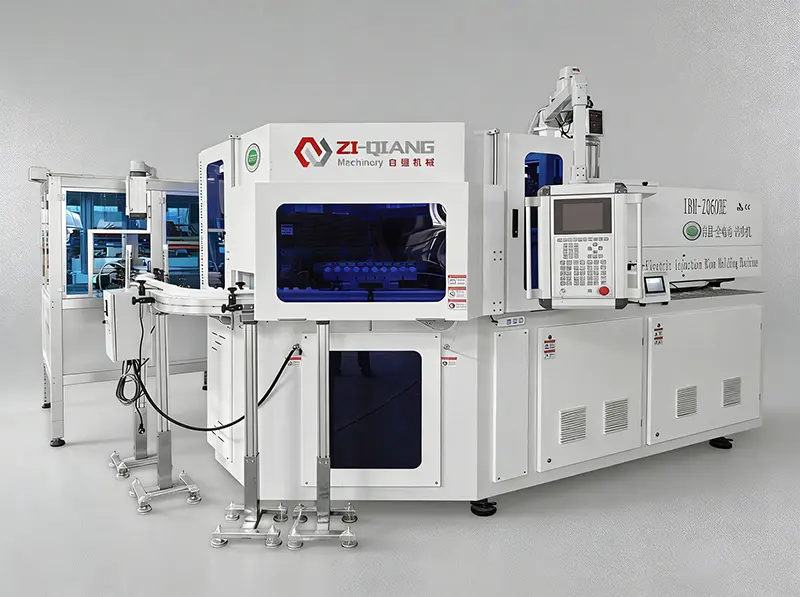

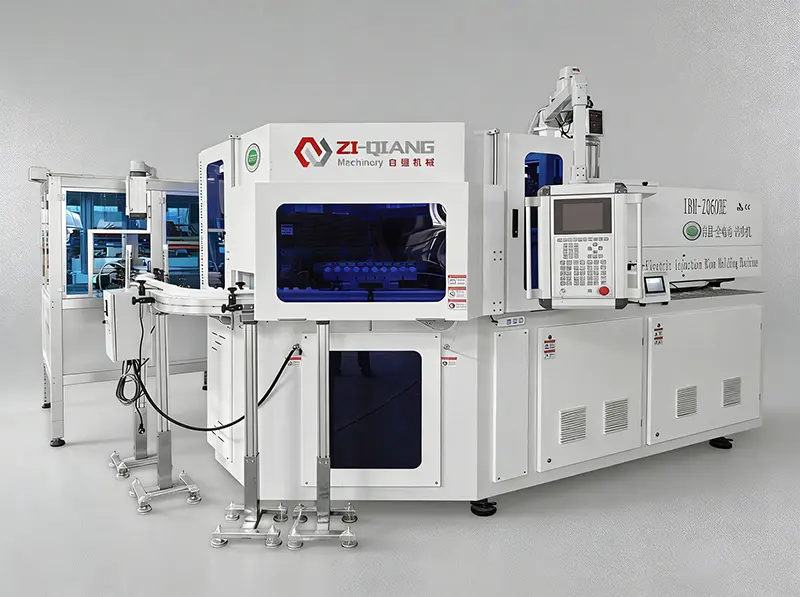

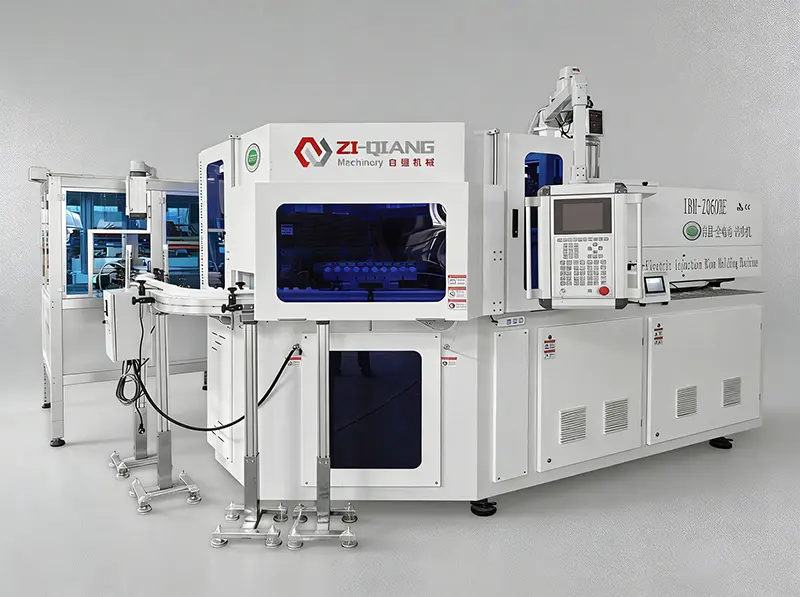

ZQ60HE High-Speed Fully Electric Injection Blow Molding Machine

All movements of this injection-blow molding machine are servo-driven, eliminating hydraulic oil usage and related pollution risks. It delivers a 20% faster cycle than traditional hydraulic machines: for 30ml bottles, each cycle takes 8.2 seconds, with a daily output of 105,000 bottles and a peak capacity of 115,000 bottles/24h. Energy efficiency is improved by 30%, consuming just 12 kWh per hour for 30ml bottle production. With a significantly lower noise level, the machine is equipped with absolute encoders in its servo system to ensure exceptional repeatability and processing precision. A special clamping mechanism offers adjustable clamping force (40-80 tons) to adapt to diverse product specifications. The bottom-up structural design prevents lubricating oil from entering the mold area, complying with strict hygienic requirements for pharmaceutical packaging and high-grade plastic bottles. Fully customizable, it adopts an electric cylinder injection unit for enhanced injection stability and reduced maintenance costs. The conveyor can be connected to visual inspection systems (for foreign particles, insufficient bottle mouth material, uneven bottoms), side-leak testers, labeling machines, and automatic packaging equipment, enabling fully automated unattended operation.

| ITEM |

Unit |

ZQ60HE |

| Injection System |

| Screw Diameter |

mm |

45/50 |

| Screw L/D |

% |

22:1 |

| Injection weight |

g |

280/360 |

| Heating power |

KW |

10.3+4 |

| Number of barrel zone |

- |

3+N |

| Injection stroke |

mm |

200 |

| Clamping System |

| Clamping force of injection |

KN |

400-800 |

| Opening stroke for injection |

mm |

140 |

| Clamping force of blowing |

KN |

200 |

| Opening stroke for blowing |

mm |

140 |

| Lifting height of rotary table |

mm |

- |

| Mould |

| Max.Platen size(L x W) |

mm |

600×420 |

| Mold thickness |

mm |

240 |

| Dia.of bottle |

mm |

120 |

| Bottle height |

mm |

220 |

| Suitable bottle height |

mm |

1-2000 |

| Stripping stroke |

mm |

220 |

| Hydraulic system Hydraulic |

| Pressure |

Map |

- |

| Motor power |

KW |

- |

| Dry cycle |

S |

2.5 |

| Total Power |

KW |

90 |

| Operating power |

% |

15-25 |

| Others |

| Min.Air pressure of compressed air |

MPa |

0.8-1.2 |

| Compressed air capacity |

M3/min |

- |

| Water flowage |

M3/h |

- |

| Cooling water pressure |

MPa |

- |

| Dimension(L x W x H) |

M |

3×1.3×1.7 |

| Net weight |

Ton |

6 |

| Injection Servo Motor |

KW |

22 |

| Material Feeding Servo Motor |

KW |

18 |

| Clamping Servo Motor |

KW |

15KW+15KW |

| Carriage Movement Servo Motor |

KW |

1 |

| Ejector Servo Motor |

KW |

0.4 |

| Rotary Servo Motor |

KW |

2.9 |