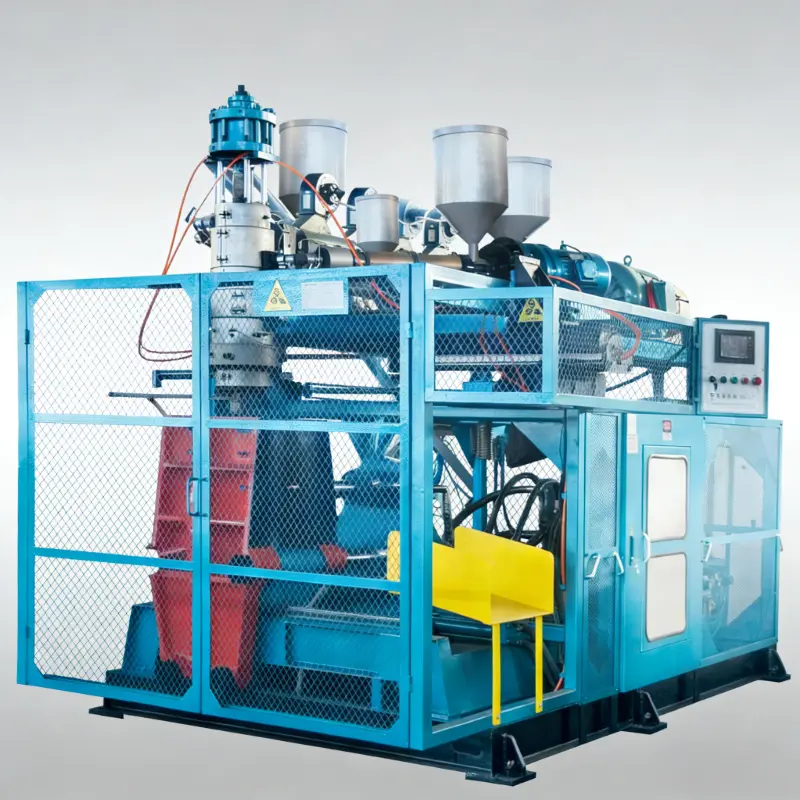

The Extrusion Blow Moulding Machine independently developed by our company is characterized by strong material adaptability. It can process PE, PP, PVC and other polymer materials, and produce hollow products of different specifications and sizes through reasonable parameter setting. With multi-layer co-extrusion function, it can produce products with view stripes, which is widely used in chemical industry and other industries.

| Max. Product Volume | (L) | 30 |

| Theoretical Output | (PC/h) | 550 |

| Screw Diameter | (mm) | 90 |

| Screw L/D ratio | (L/D) | 25 |

| Screw drive power | (KW) | 45 |

| Screw heating capacity | (KW) | 20 |

| Output of HDPE | (kg/h) | 150 |

| Oil pump drive power | (KW) | 15-22 |

| Clamping force | (KN) | 280 |

| Platen size | (W×H)mm | 600×660 |

| Platen Opening Stroke | (mm) | 350-800 |

| Storage Capacity(Optional) | (L) | 4.8 |

| Max. Die Diameter | (mm) | 260 |

| Die heat capacity | (kw) | 7.5 |

| Average Energy Consumption | (kw/h) | 35.2 |

| Blowing pressure | (Mpa) | 0.6 |

| Air Consumption | (M³/MIN) | 1.0 |

| Cooling water pressure | (Mpa) | 0.3 |

| Water consumption | (L/MIN) | 95 |

| Size of machine | (L×W×H)/m | 4.6×2.2×3.2 |

| Weight of machine | (TON) | 12.5 |