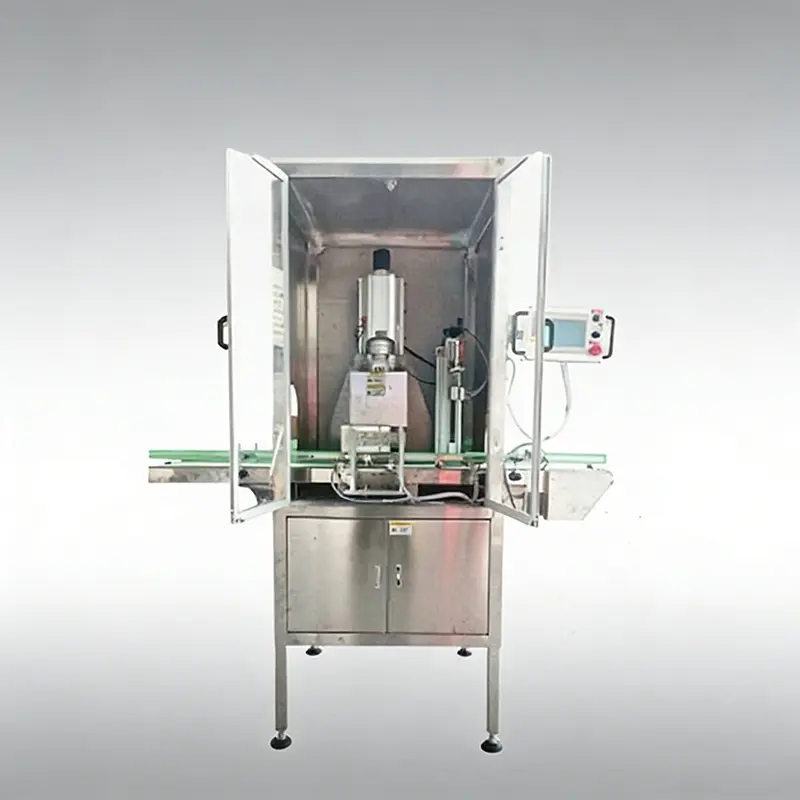

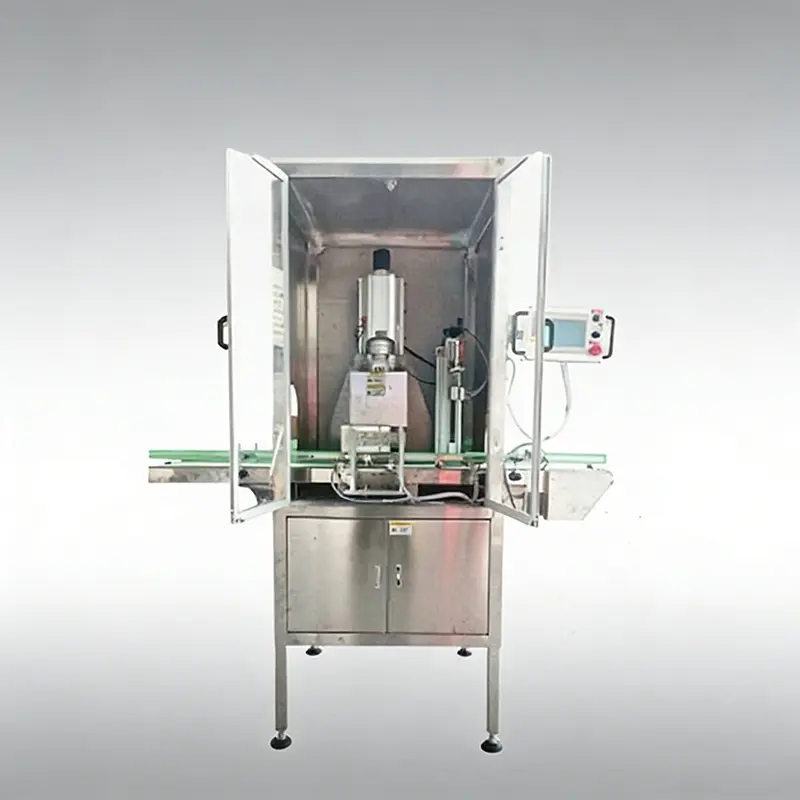

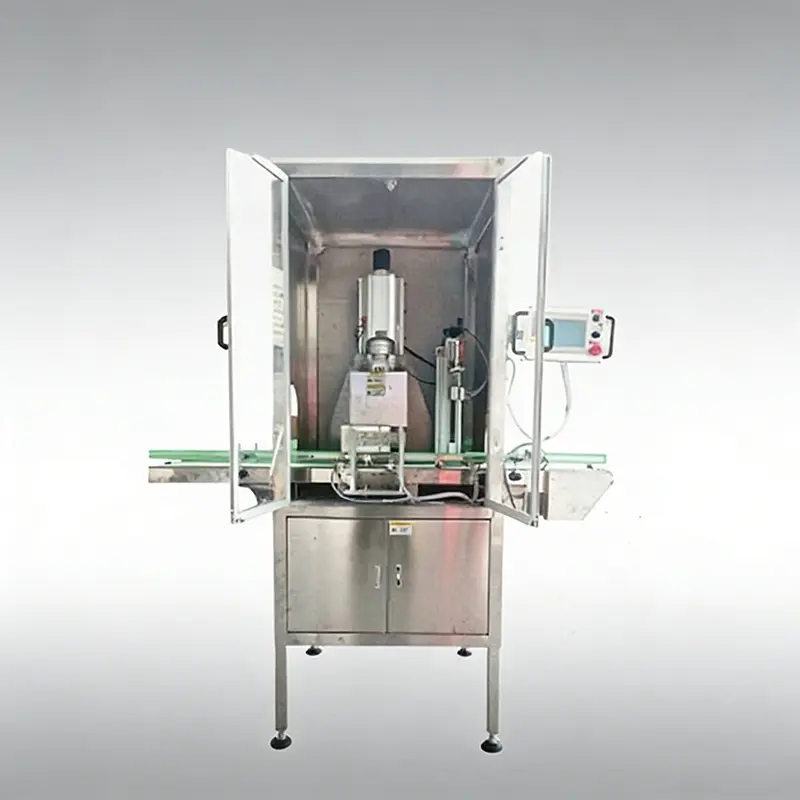

Precision Trimming, Efficient Production! It features fully automatic operation, slashing labor costs while eliminating manual errors for consistent quality. Adopting advanced soft cutting technology, it delivers smooth, burr-free bottle mouths without generating debris, laying a solid foundation for subsequent capping and labeling. Compatible with PE, PVC, PP, PET, and PC materials, it fits round, square, and various bottle types, easily integrating into existing production lines. With energy-saving design and recyclable trimmed materials, it reduces environmental impact and raw material waste, becoming an indispensable core equipment for beverage, daily chemical, and pharmaceutical industries.

| Models | ZQ-QK161 | ZQ-QK-162 |

| External dimensions | 1600×950×1570mm | 1600×950×1570mm |

| Conveying height | 800-1150mm | 800-1150mm |

| Incision station | 1 | 2 |

| Incision rate | 500-600PCS/h | 1000-1100PCS/h |

| Use the air source | ≥0.5Mp | ≥0.5Mp |

| Total power | 0.2kW | 0.2kW |